| Func. | Order Code | Description | |||||||

| Item | KH105- |

| Multi Channel Process Indicator | ||||||

| Size | F- |

| 72X72X105mm | ||||||

| FT- |

| 320x120x250mm( desktop) | |||||||

| Input Channels | 1 |

| One channel | ||||||

| 2 |

| Two channels | |||||||

| 3 |

| Three channels | |||||||

| 4 |

| Four channels | |||||||

| OUT1 | N- |

| None | ||||||

| R2A- |

| Relay alarm output: NO ,30VDC/3A, 220VAC/3A | |||||||

| R2B- |

| Relay alarm output :NC ,30VDC/0.8A, 220VAC/0.8A | |||||||

| U1- |

| Isolated auxiliary 5VDC power supply for transmitter, sensor and other device, max.100mA | |||||||

| U2- |

| Isolated auxiliary 12VDC power supply for transmitter, sensor and other device, max.100mA | |||||||

| U3- |

| Isolated auxiliary 24VDC power supply for transmitter, sensor and other device, max.100mA | |||||||

| OUT2 | N- |

| None | ||||||

| R2C- |

| Relay alarm output: NO+NC ,30VDC/3A, 220VAC/3A | |||||||

| S1- |

| RS485 communication port Modbus-RTU | |||||||

| S2- |

| RS232 communication port, Modbus-RTU | |||||||

| P- |

| RS232 Printing port for mini printer | |||||||

| Input Signal | N- |

| Universal Input | ||||||

| I- |

| 4-20mA , with 250Ω resistance built-in | |||||||

| X- |

| 0-10mA, with 500Ω resistance built-in | |||||||

| U- |

| 0-5V or 1-5V | |||||||

| K- |

| Thermocouple: K, J,N | |||||||

| E- |

| Thermocouple: E, | |||||||

| B- |

| Thermocouple: S, T, B | |||||||

| P- |

| Pt100, CU50, CU100 | |||||||

| Power Supply | N- | 220VAC, 50HZ ,85-240VAC | |||||||

| A- |

| 110VAC, 60HZ,85-240VAC | |||||||

| D- |

| 24VDC | |||||||

| Mini printer (working with code “P”) | N | No | |||||||

| W | Yes, kehao WH-A5 dot matrix mini printer | ||||||||

| Func. | Order Code | Description | ||||||||||

| Item | KH105- |

| Multi channel process indicator | |||||||||

| Size | D- |

| 160x80x105mm | |||||||||

| DT- |

| 320x120x250mm( desktop) | ||||||||||

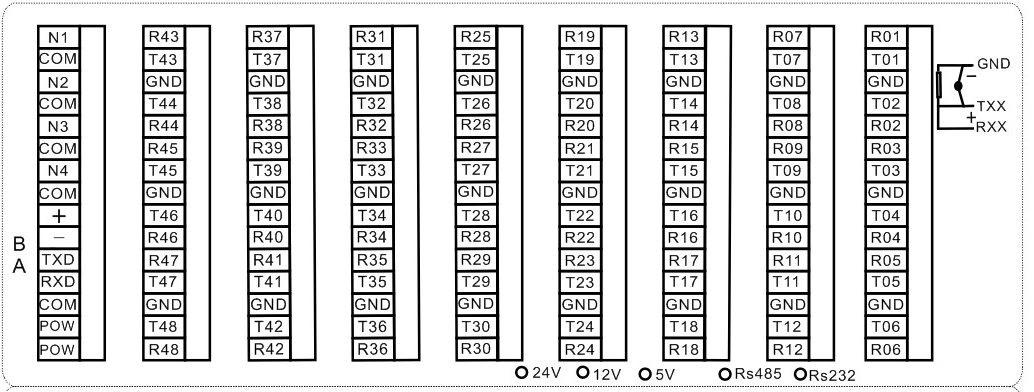

| Input Channels | 1 |

| One channel | |||||||||

| 2 |

| Two channel | ||||||||||

| … |

| ……….. | ||||||||||

| 48 |

| 48 channels | ||||||||||

| Relay Alarm Output (max. 4 output when CH17 to CH48) | N |

| None | |||||||||

| 1 |

| one alarm | ||||||||||

| 2 |

| two alarms | ||||||||||

| .... |

| ……. | ||||||||||

| 8 |

| 8 alarms | ||||||||||

| Relay Alarm Output Mode | N |

| None | |||||||||

| R1A- |

| NO (30VDC/0.8A, 220VAC/0.8A) | ||||||||||

| R1B- |

| NC (30VDC/0.8A, 220VAC/3A) | ||||||||||

| Communication and Printing | N- |

| None | |||||||||

| S1- |

| RS485 communication interface | ||||||||||

| S2- |

| RS232 communication interface | ||||||||||

| P- |

| RS232 printing interface | ||||||||||

| Isolated auxiliary Power Supply for Transmitter and sensors or other device | N- |

| None | |||||||||

| U1- |

| 5VDC built in, max. 100mA | ||||||||||

| U2- |

| 12VDC built in, max.100mA | ||||||||||

| U3- |

| 24V DC built in, max100mA | ||||||||||

| Input Signal | N |

| Universal Input | |||||||||

| I- |

| 4-20mA , with 250Ω resistance built-in | ||||||||||

| X- |

| 0-10mA, with 500Ω resistance built-in | ||||||||||

| U- |

| 0-5V or 1-5V | ||||||||||

| K- |

| Thermocouple: K, J, N | ||||||||||

| E- |

| Thermocouple: E | ||||||||||

| B- |

| Thermocouple: B, S,T | ||||||||||

| P- |

| Pt100, CU50,CU500 | ||||||||||

| Power Supply | N | 220VAC, 50HZ ,85-240VAC | ||||||||||

| A- |

| 110VAC, 60HZ,85-240VAC | ||||||||||

| Mini Printer (working with code “P” together) | N | None | ||||||||||

| W- | Yes, Kehao mini dot-matrix printer | |||||||||||

| DCS software for RS485,RS232 MODBUS-RTU communication , real time monitoring and recording | N | None | ||||||||||

| DCS | Yes, Kehao DCS software | |||||||||||

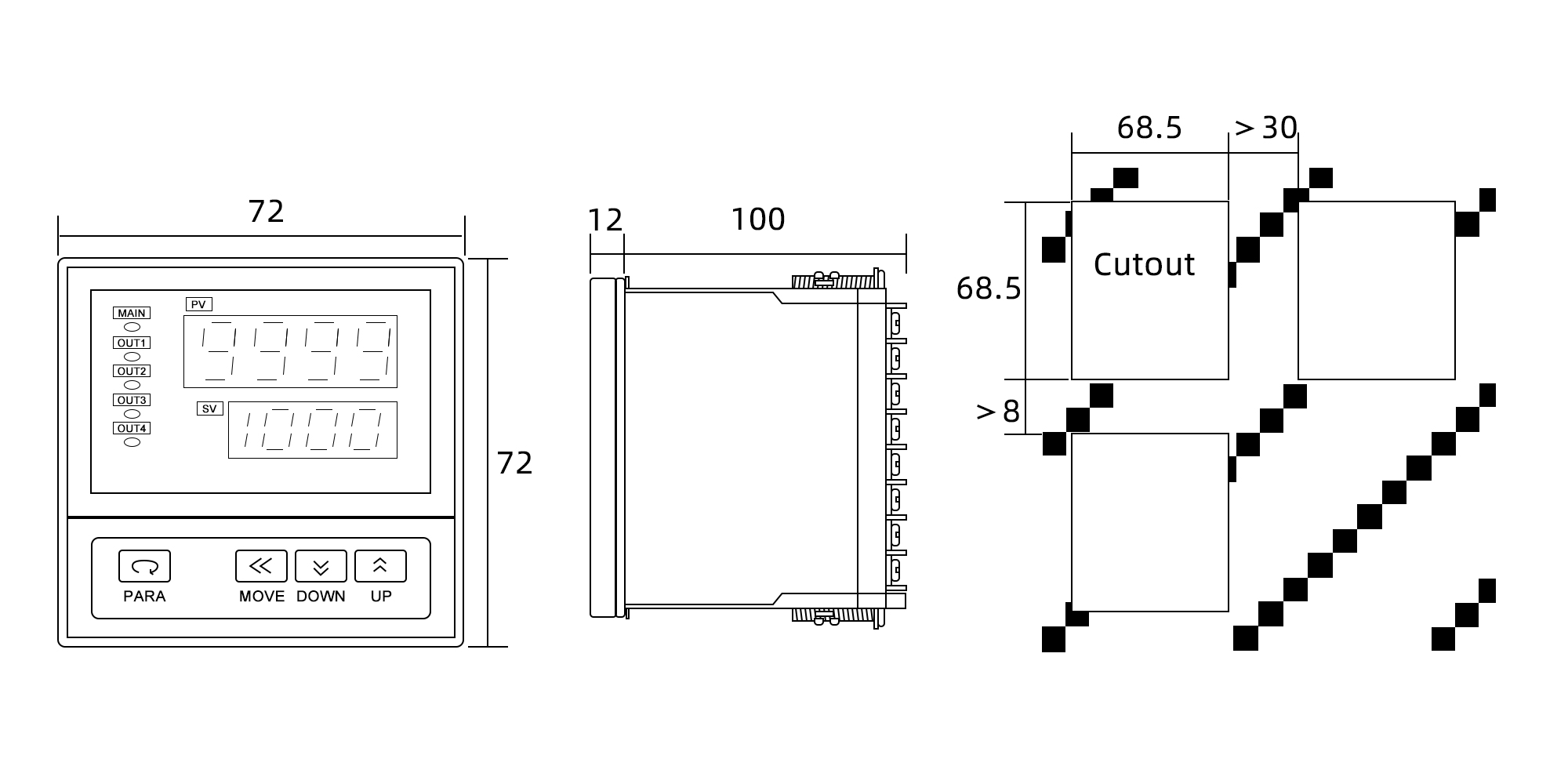

Installation Dimension(mm) : Size: F:72X72x105mm

Installation Dimension(mm) : Size: F:72X72x105mm  Size: D: 160x80x105mm

Size: D: 160x80x105mm

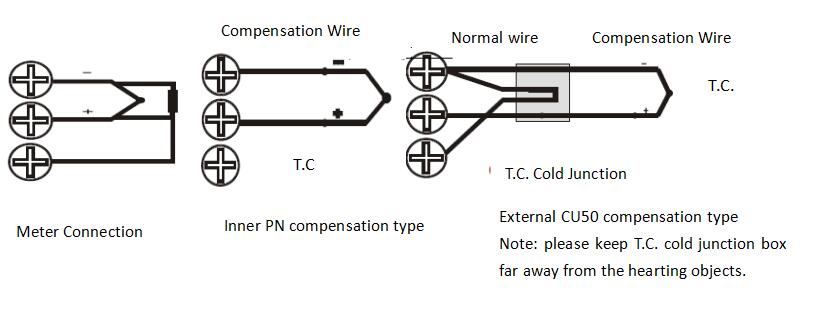

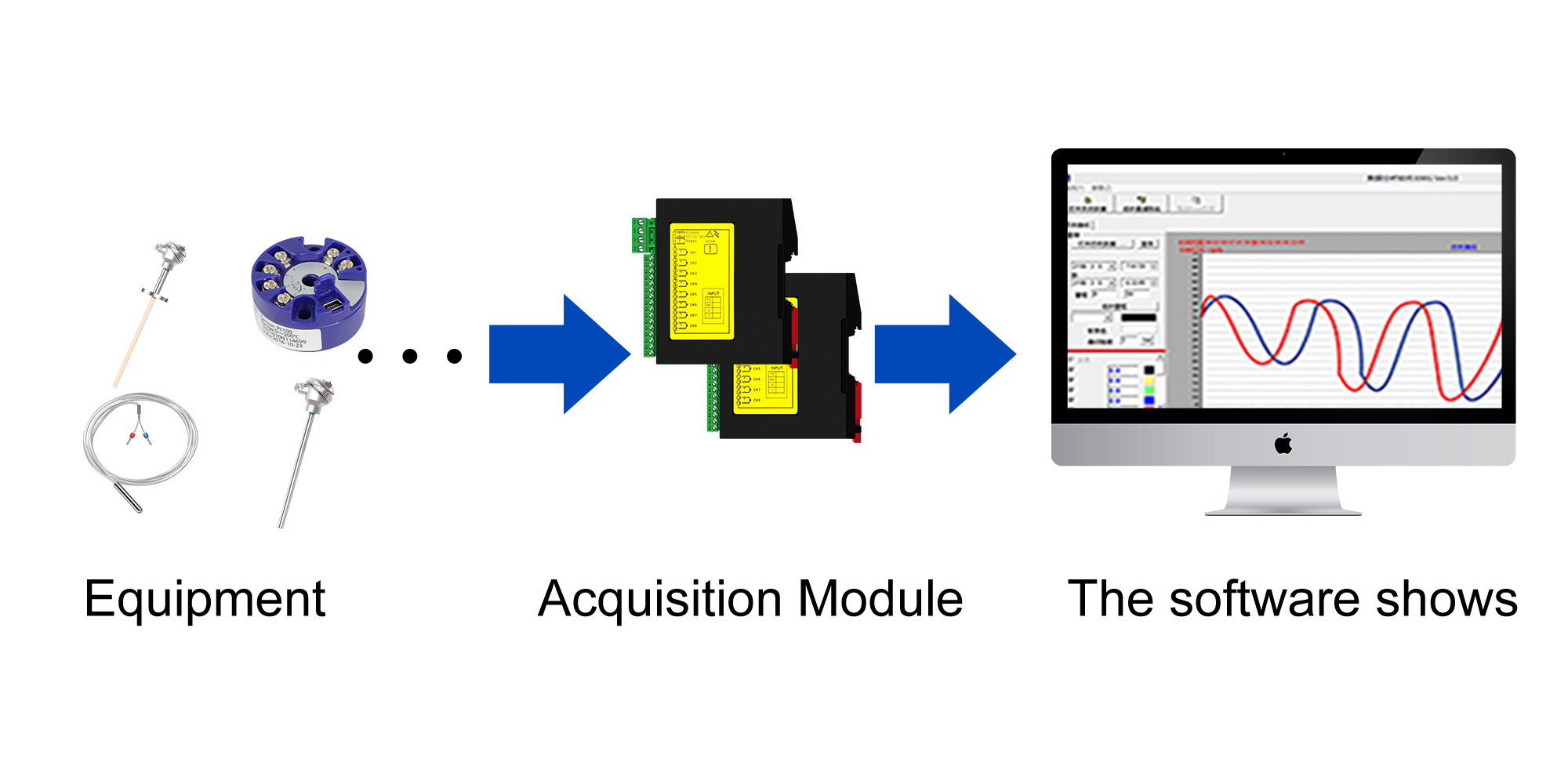

When T.C .input, T.C. cold-junction temperature compensation will be needed according to its temperature measuring principle (Please refer relative information).There are three kinds of compensation modes: NULL(no compensation, used for measure), doid (Inner auto temperature component),Cu50(external RTD Cu50 compensation).”diod” compensation can measure the terminal temperature on the bear of the meter and compensate for T.C. cold –junction compensation. But because of the error of measuring component, meter itself heating and other heat source near meter, it usually leads to big deviation of the compensation by “diod” compensation, whose error can be up to 2-4℃ at worst. Please adopts “Cu50” compensation if require higher measuring accuracy: Please connect a external box and put Cu50Cu resistance purchased in your side and the T.C. cold-junction together and keep them far away from kinds of heating sources, If so, the inconsistency of the measuring caused by compensation is less than 0.5℃。If change external Cu resistance to accurate resistance, it can also achieve compensation function of constant temperature bath. For example, please connect 55Ω resistance externally with relative temperature 23.4℃ by Cu50 index table; please put T.C. cold –junction .in constant temperature bath in 23.4℃ to get more accurate compensation, which is higher than Cu resistance compensation. The connection of the two ways of cold-junction compensation as follows:The equipment uses RS485 communication connection acquisition card to achieve real-time recording, monitoring and query

When T.C .input, T.C. cold-junction temperature compensation will be needed according to its temperature measuring principle (Please refer relative information).There are three kinds of compensation modes: NULL(no compensation, used for measure), doid (Inner auto temperature component),Cu50(external RTD Cu50 compensation).”diod” compensation can measure the terminal temperature on the bear of the meter and compensate for T.C. cold –junction compensation. But because of the error of measuring component, meter itself heating and other heat source near meter, it usually leads to big deviation of the compensation by “diod” compensation, whose error can be up to 2-4℃ at worst. Please adopts “Cu50” compensation if require higher measuring accuracy: Please connect a external box and put Cu50Cu resistance purchased in your side and the T.C. cold-junction together and keep them far away from kinds of heating sources, If so, the inconsistency of the measuring caused by compensation is less than 0.5℃。If change external Cu resistance to accurate resistance, it can also achieve compensation function of constant temperature bath. For example, please connect 55Ω resistance externally with relative temperature 23.4℃ by Cu50 index table; please put T.C. cold –junction .in constant temperature bath in 23.4℃ to get more accurate compensation, which is higher than Cu resistance compensation. The connection of the two ways of cold-junction compensation as follows:The equipment uses RS485 communication connection acquisition card to achieve real-time recording, monitoring and query  Cloud acquisition software, only NEED 4G wireless module communication, no wiring, easy to install! Mobile phone computer remote view data or graph, at the same time with SMS alarm function.

Cloud acquisition software, only NEED 4G wireless module communication, no wiring, easy to install! Mobile phone computer remote view data or graph, at the same time with SMS alarm function.