summary

The eddy current sensor can measure the distance between the measured metal conductor and the probe surface statically and dynamically with non-contact, high linearity and high resolution. Such as the radial vibration, amplitude and axial position of the shaft. Among all the fault symptoms related to mechanical state, mechanical vibration measurement is the most authoritative because it contains amplitude, phase and frequency information at the same time.

The eddy current sensor can measure the distance between the measured metal conductor and the probe surface statically and dynamically with non-contact, high linearity and high resolution. Such as the radial vibration, amplitude and axial position of the shaft. Among all the fault symptoms related to mechanical state, mechanical vibration measurement is the most authoritative because it contains amplitude, phase and frequency information at the same time.

Title goes here.

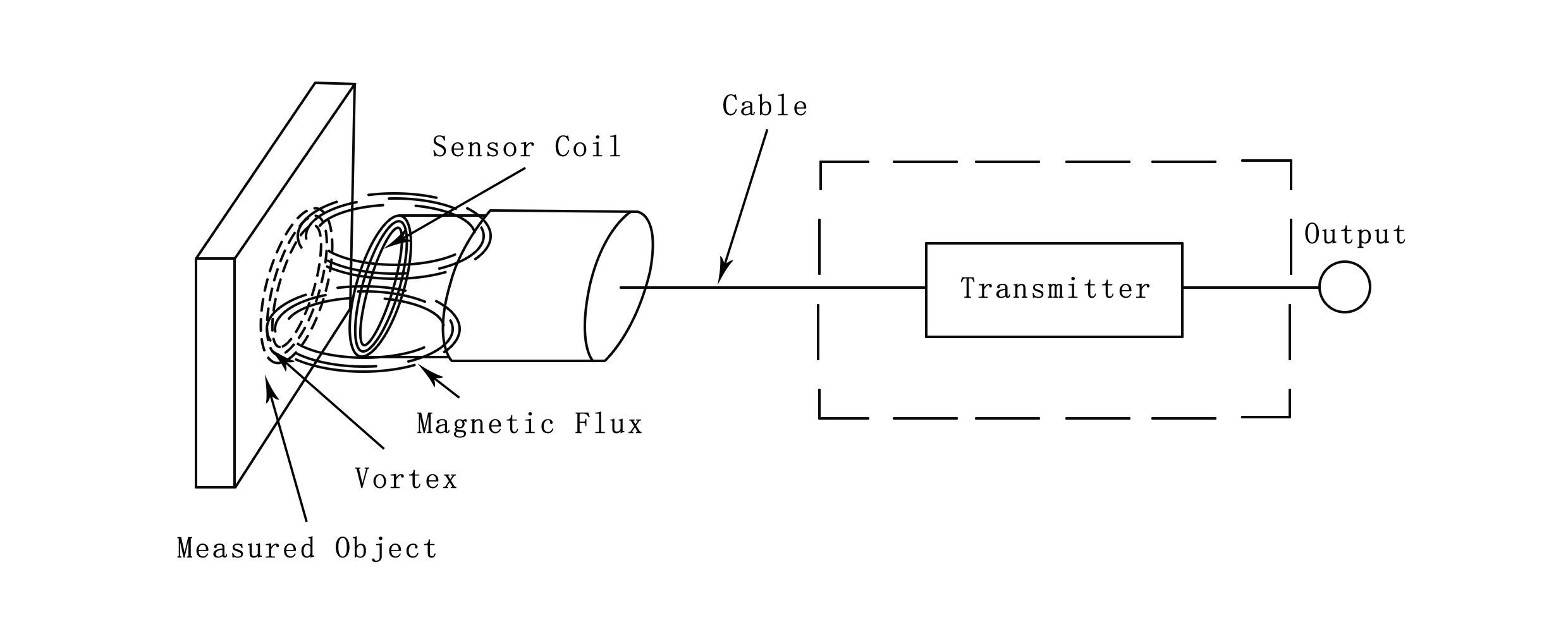

Principle: when the distance between the measured metal and the probe changes, the Q value of the coil in the probe also changes. The change of Q value causes the change of oscillation voltage amplitude, and the oscillation voltage varying with the distance is converted into voltage (current) change after detection, filtering, linear compensation, amplification and normalization, and finally the mechanical displacement (GAP) is converted into voltage (current).

Title goes here.

1、 Practical application

Eddy current sensor system is widely used in electric power, petroleum, chemical industry, metallurgy and other industries and some scientific research institutions. Online measurement and protection of radial vibration, axial displacement, Keyphasor, shaft speed, differential expansion, eccentricity, rotor dynamics research and part size inspection of large rotating machinery shafts such as steam turbine, water turbine, blower, compressor, air separation unit, gearbox and large cooling pump.

Axial displacement measurement

The measurement of axial displacement can indicate the axial clearance or relative instantaneous displacement change between rotating parts and fixed parts, so as to prevent the damage of the machine.

●wear and failure of thrust bearing ● wear and failure of balance piston

●looseness of thrust flange ● locking of coupling, etc.

Vibration measurement

By measuring the radial vibration, we can see the working state of the bearing and the imbalance and medium mechanical failure of the rotor.

Eccentricity measurement

Eccentricity is the measurement of shaft bending at low speed, which can be caused by the following conditions:

●Original mechanical bending · bending caused by temporary temperature rise ● in the static state, there must be some downward bending, sometimes called gravity bending.

Differential expansion measurement

For steam turbine generator units, during startup and shutdown, due to different metal materials, different thermal expansion coefficients and different heat dissipation, the thermal expansion of the shaft may exceed that of the shell.

Speed measurement

For all rotating machinery, it is necessary to monitor the rotating speed of the rotating machinery shaft. The rotating speed is an important index to measure the normal operation of the machine.

2、Installation requirements

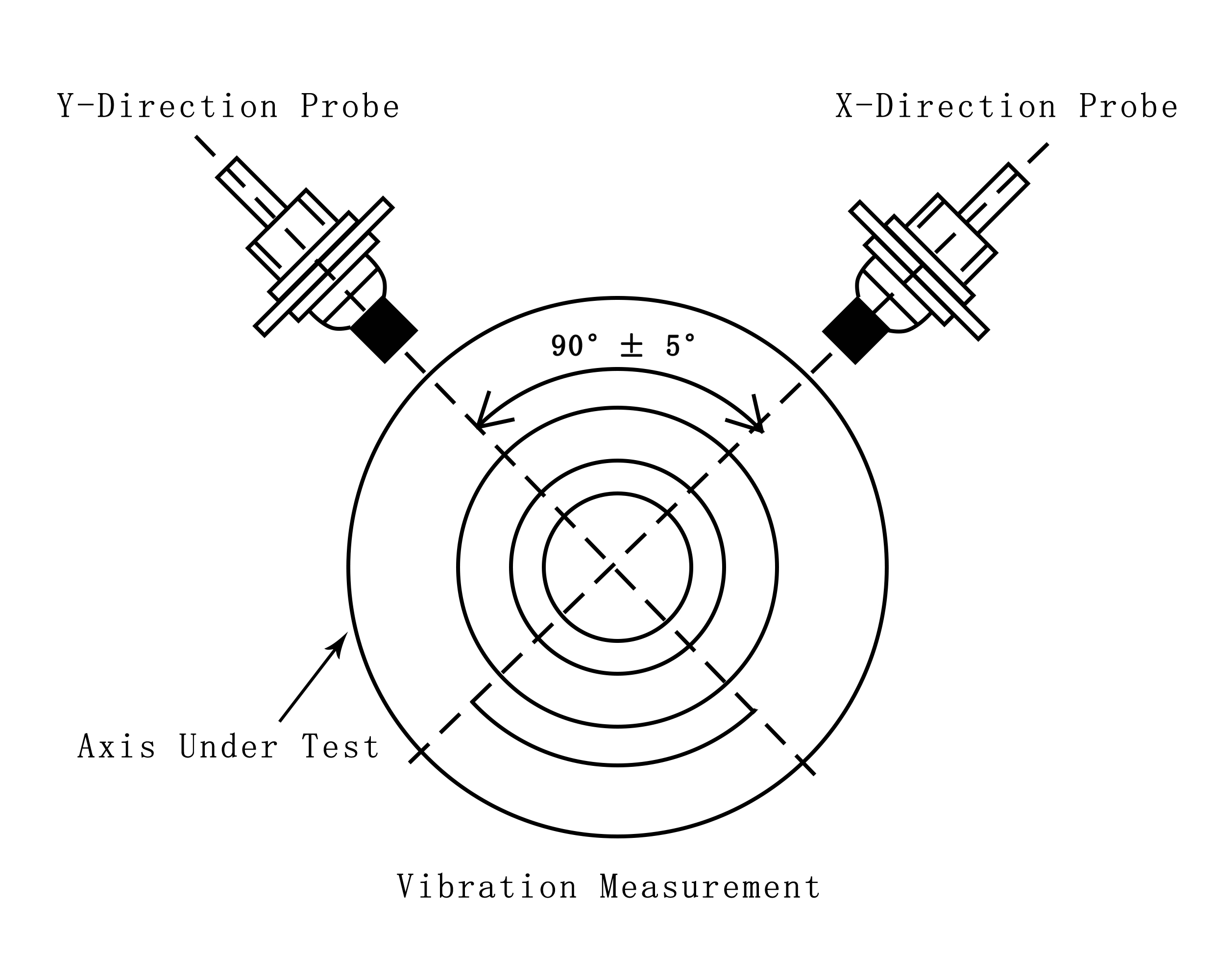

Axial vibration measurement

When the radial vibration of the shaft needs to be measured, the diameter of the shaft is required to be more than three times the diameter of the probe. Two sensor probes shall be installed at each measuring point at the same time, and the two probes shall be installed on the same plane on both sides of the bearing, separated by 90 º ± 5 º. Since the bearing cover is generally divided horizontally, the two probes are usually installed at 45 º on each side of the vertical centerline. From the end of the prime mover, they are respectively defined as X probe (horizontal direction) and Y probe (vertical direction). The X direction is on the right side of the vertical centerline and the Y direction is on the left side of the vertical centerline.

Axial displacement measurement

When measuring the axial displacement of the shaft, the measuring surface should be integral with the shaft. This measuring surface is a probe ring with the center line of the probe as the center and 1.5 times the width.

Eddy current sensor system is widely used in electric power, petroleum, chemical industry, metallurgy and other industries and some scientific research institutions. Online measurement and protection of radial vibration, axial displacement, Keyphasor, shaft speed, differential expansion, eccentricity, rotor dynamics research and part size inspection of large rotating machinery shafts such as steam turbine, water turbine, blower, compressor, air separation unit, gearbox and large cooling pump.

Axial displacement measurement

The measurement of axial displacement can indicate the axial clearance or relative instantaneous displacement change between rotating parts and fixed parts, so as to prevent the damage of the machine.

●wear and failure of thrust bearing ● wear and failure of balance piston

●looseness of thrust flange ● locking of coupling, etc.

Vibration measurement

By measuring the radial vibration, we can see the working state of the bearing and the imbalance and medium mechanical failure of the rotor.

Eccentricity measurement

Eccentricity is the measurement of shaft bending at low speed, which can be caused by the following conditions:

●Original mechanical bending · bending caused by temporary temperature rise ● in the static state, there must be some downward bending, sometimes called gravity bending.

Differential expansion measurement

For steam turbine generator units, during startup and shutdown, due to different metal materials, different thermal expansion coefficients and different heat dissipation, the thermal expansion of the shaft may exceed that of the shell.

Speed measurement

For all rotating machinery, it is necessary to monitor the rotating speed of the rotating machinery shaft. The rotating speed is an important index to measure the normal operation of the machine.

2、Installation requirements

Axial vibration measurement

When the radial vibration of the shaft needs to be measured, the diameter of the shaft is required to be more than three times the diameter of the probe. Two sensor probes shall be installed at each measuring point at the same time, and the two probes shall be installed on the same plane on both sides of the bearing, separated by 90 º ± 5 º. Since the bearing cover is generally divided horizontally, the two probes are usually installed at 45 º on each side of the vertical centerline. From the end of the prime mover, they are respectively defined as X probe (horizontal direction) and Y probe (vertical direction). The X direction is on the right side of the vertical centerline and the Y direction is on the left side of the vertical centerline.

Axial displacement measurement

When measuring the axial displacement of the shaft, the measuring surface should be integral with the shaft. This measuring surface is a probe ring with the center line of the probe as the center and 1.5 times the width.

3、selection of eddy current sensor

Sensor selection

KH900-A□-B□-C□-D□

A: Unthreaded length (2-250mm or 0.1-9.9in)

B: Total length of probe (20-500mm or 0.8-20in)

C: Cable length (0.5-10m)

D: Cable material (ordinary and armored)

Transmitter selection

KH900-A□□-B□□

A: Output signal

00 - 24VDC power supply, unlimited - 2 ~ - 18vdc output

01 - 24VDC power supply, unlimited - 4 ~ - 20Vdc output

02 + 24VDC power supply, unlimited amplitude 4 ~ 20mA output

03 + 24VDC power supply, limiting 4 ~ 20mA output

04 + 24VDC power supply, unlimited amplitude 0 ~ 10mA output

05 + 24VDC power supply, limiting 0 ~ 10mA output

06 + 24VDC power supply, unlimited amplitude 1 ~ 5VDC output

07 + 24VDC power supply, limiting 1 ~ 5VDC output

08 + 24VDC power supply, unlimited amplitude 2 ~ + 18vdc output

09 + 24VDC power supply, unlimited amplitude 4 ~ 20Vdc output

10 ± 12VDC power supply, unlimited amplitude 0 ~ 5VDC output

11 ± 12VDC power supply, limiting 0 ~ 5VDC output

12 ± 15Vdc power supply, unlimited amplitude, 1 ~ 5VDC output

13 ± 15Vdc power supply, limiting 1 ~ 5VDC output

14 ± 15Vdc power supply, unlimited amplitude 0 ~ 10VDC output

15 ± 15Vdc power supply, limiting 0 ~ 10VDC output

16 ± 12VDC power supply, unlimited ± 5VDC output

17 ± 12VDC power supply, limiting ± 5VDC output

18 ± 15Vdc power supply, unlimited ± 10VDC output

19 ± 15Vdc power supply, limiting ± 10VDC output

20 ± 18vdc power supply, limiting 4 ~ 20mA output

KH900-A□-B□-C□-D□

A: Unthreaded length (2-250mm or 0.1-9.9in)

B: Total length of probe (20-500mm or 0.8-20in)

C: Cable length (0.5-10m)

D: Cable material (ordinary and armored)

Transmitter selection

KH900-A□□-B□□

A: Output signal

00 - 24VDC power supply, unlimited - 2 ~ - 18vdc output

01 - 24VDC power supply, unlimited - 4 ~ - 20Vdc output

02 + 24VDC power supply, unlimited amplitude 4 ~ 20mA output

03 + 24VDC power supply, limiting 4 ~ 20mA output

04 + 24VDC power supply, unlimited amplitude 0 ~ 10mA output

05 + 24VDC power supply, limiting 0 ~ 10mA output

06 + 24VDC power supply, unlimited amplitude 1 ~ 5VDC output

07 + 24VDC power supply, limiting 1 ~ 5VDC output

08 + 24VDC power supply, unlimited amplitude 2 ~ + 18vdc output

09 + 24VDC power supply, unlimited amplitude 4 ~ 20Vdc output

10 ± 12VDC power supply, unlimited amplitude 0 ~ 5VDC output

11 ± 12VDC power supply, limiting 0 ~ 5VDC output

12 ± 15Vdc power supply, unlimited amplitude, 1 ~ 5VDC output

13 ± 15Vdc power supply, limiting 1 ~ 5VDC output

14 ± 15Vdc power supply, unlimited amplitude 0 ~ 10VDC output

15 ± 15Vdc power supply, limiting 0 ~ 10VDC output

16 ± 12VDC power supply, unlimited ± 5VDC output

17 ± 12VDC power supply, limiting ± 5VDC output

18 ± 15Vdc power supply, unlimited ± 10VDC output

19 ± 15Vdc power supply, limiting ± 10VDC output

20 ± 18vdc power supply, limiting 4 ~ 20mA output

B: Installation mode

01 Split guide rail

02 Split screw

03 Integral thread

01 Split guide rail

02 Split screw

03 Integral thread